Reinforced retaining ring (facilitates maintenance, protects the seal against tearing and acts as a deflector)

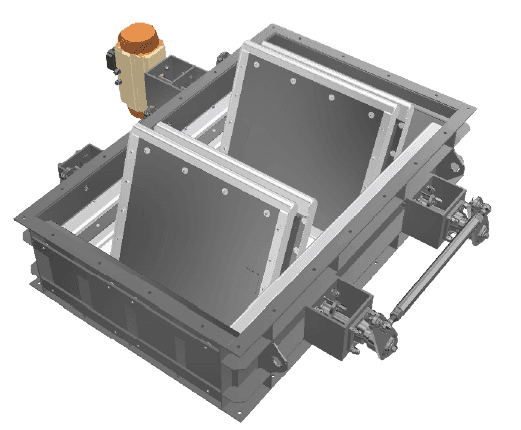

Damper valves DV LDV as T (tandem) or DB (double blade) execution are of welded construction and are designed as 100% tight valves to shut-off media such as air or process gas.

The design involves injecting air produced by a fan between the two discs, in order to create overpressure and ensure a seal between the upstream and downstream sides of the valve.

Due to their material selection, precise execution and control technology, these dampers are usually important components of a plant with high expectations of reliability. As such, they are subject to thorough testing, especially concerning their tightness.

Industrial Applications of Rectangular Butterfly Dampers

- Flue gas desulphurisation

- Dust extraction of furnaces

- Utilisation of SO2, SO3, NOX

- Air-tight sealing of production processes in smelters

- Chemical and paper industry

- Glass smelters

- Non-ferrous metals smelters

Technical Characteristics of Air Sealed Multi-Blade Dampers

Dimensions range MLDVR-T : max. 12000 x 12000mm (larger sizes on request)

Design pressure : < 0,5 bar

Temperature range: -20°C up to +750°C or acc. to customer request (max. working temperature up to 1100ºC)

Gland packing : Graphite (other depending on medium and temperature)

Installation of dampers : face-to-face length, working position (acc. to customer requirements)

Materials: Depending on medium, temperature, customer reqiurements

Actuators:

- Pneumatic quarter turn or linear actuators with accessories acc. to technical and customer requirements

- Electric quarter turn actuators with accessories acc. to technical and customer requirements

Special design:

- Actuating systems equipped with electric actuators, electromagnetic couplings,

hydraulic dampers (quick closing or quick opening valves for emergency modes of operation) - Actuating systems with counterweights or return springs (quick mechanical safety actuators in case of emergency – closing or opening)